| Ossila Slot Die Coater |

| |

|

| |

| Overview |

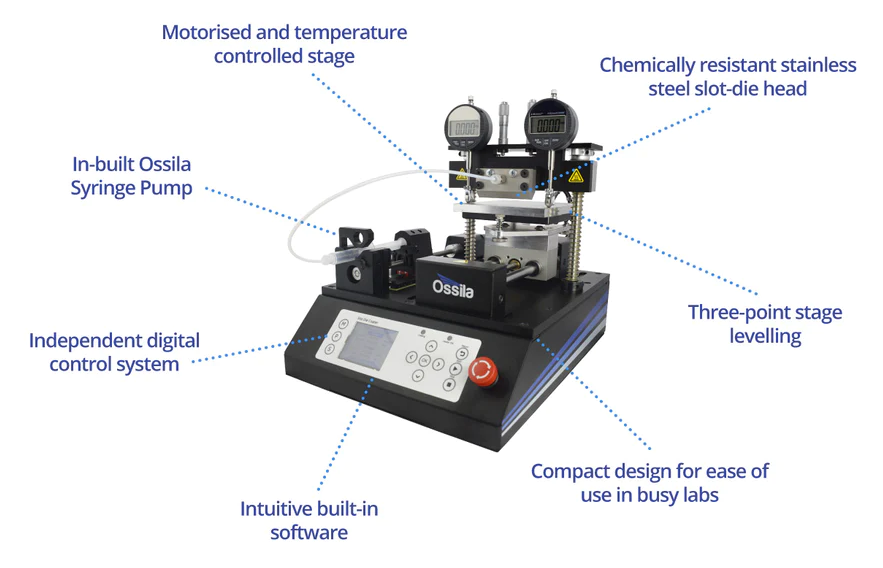

Part of the Institute of Physics award-winning solar cell prototyping platform, the Ossila Slot Die Coater is much smaller than other models on the market but just as precise. Despite its reduced size, it also includes an integrated syringe pump for synchronised start and end times.

Our slot die coater is fully operable via the digital controls on the unit itself. This allows you to easily programme multi-step processes, where different parts of the system can each be controlled independently. Up to 20 of these programmes can be saved, each of which can contain up to 50 steps, for easy repeat experiments. You have control over temperature, substrate speed and alignment, solution flow rate, channel thickness, head height, and more. |

| |

| |

| Features |

| • Space-Saving Design |

• Temperature Control |

| • Easy Set Up |

• Wide Range of Substrate Speeds |

| • High Uniformity |

• Precision Alignment |

| • Variable Channel Thickness |

• Head Height Control |

| • Uniform Flow Rates and thicknesses |

• Integrated Software |

|

| |

| |

|

| |

| |

| Specification |

|

| Maximum Hotplate Temperature: |

120 °C (248 °F) |

| Stage Surface Roughness (RMS): |

<3 μm* |

| Stage Surface Flatness: |

<20 μm* |

| Linear Motion Levelness: |

<50 μm variation over 100 mm (0.05%)* |

| Stage Travel Length: |

100 mm (maximum) |

| Minimum Stage Speed: |

100 μm.s-1 |

| Maximum Stage Speed: |

50 mm.s-1 |

| Maximum Head to Substrate Travel Distance: |

13 mm |

| Power Supply |

DC 24 V, 6.2 A, via 100 – 240 V 50/60 Hz power adapter |

| Dimensions (D x W x H) |

360 mm x 280 mm x 190 mm |

| Weight |

<10 kg |

| |

|

| *Values determined at a stage temperature of 21 °C (69.8 °F). |

| |

| |

| In-built Syringe Pump |

| Minimum Syringe Speed |

12 μm.s-1 |

| Maximum Syringe Speed |

5 mm.s-1 |

| |

| |

| Slot Die Head |

| Slot Die Head Material |

Stainless Steel |

| Slot Die Head Coating Width |

50 mm (maximum) |

| Slot Die Shim Thickness |

100 μm / 50 μm |

| Luer Lock Adapter |

Stainless Steel M5 to Luer Lock Adapter |

| Tubing and Connector Material |

PTFE Tubing, high density PP Luer lock connectors, stainless steel Luer lock to thread connector |

|

| |

| |

| Integrated Software |

| |

|

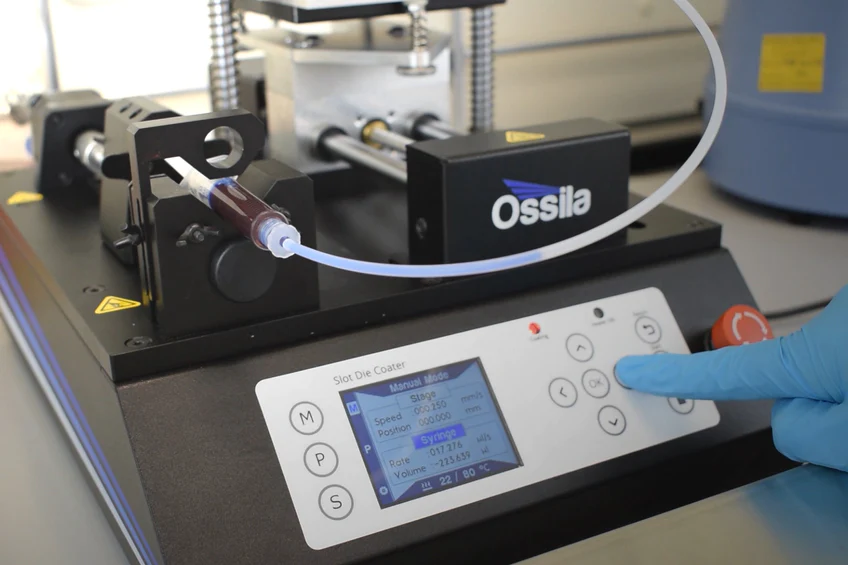

The intuitive, easy-to-use in-built software used in Ossila's other products has been incorporated into our slot die coater. A full-colour LCD provides a clear bright view of the screen, and the in-built software allows for the programming of complex multi-step processes where the different parts of the system can be controlled independently. As all elements are contained within the system, there is no need for any external computer controls - further saving money and space within the labs.

The slot die system is capable of saving 20 different programmes containing up to 50 steps each. These steps allow the user to choose various solution dispense rates, dispense volumes, dispense times, stage speed, and distance moved. Combined with the simple-to-use control panel and user interface, programming of the system can be done quickly.

Our slot die coating system comes with various safety features to ensure user protection. Maximum force settings can be applied for the syringe driver to reduce the chance of damage to delicate glass syringes. In addition, safety interlocks stop the system from crashing at the end of the travel (for both the syringe pump and motorised stage). |

|

| |

| |

| Order information |

|

Slot Die Coater |

|

Slot Die Head |

|

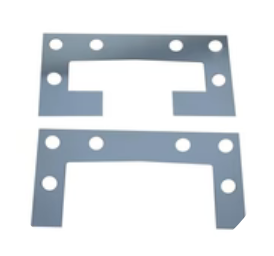

Slot Die Shims (5 pcs. / pack)

Material: Stainless steel,

Coating Width: 25mm., 50mm. or Custom.

Thickness: 0.1mm. |

|

| |

| |

| |

| |

| |

| |

| |

| |

|