| ITO PET/PEN Flim |

| |

| Indium-tin-oxide (ITO) Coated PET Flim / Pattern ITO PET |

| |

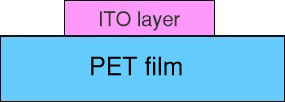

| Flim Structure |

| |

|

| |

Application of ITO coated on PET Flim |

| |

• EMI shielding

• Electroluminescent Lamps (EL),

• Touch panel electrode for LCDs, PDAs, cellphones, etc.,

• Liquid crystal devices

• Smart windows

• Transparent heaters

• Other apply |

|

| |

| Specification |

| |

|

Model |

Resistance (ohm/sq) |

Reisitance Uniformity |

Transparency at 550nm (%) |

Haze (%) |

|

XYP6 |

6 |

≤10% |

≥60 |

N/A |

0.125, 0.175 |

XYP15 |

15 |

≤10% |

≥75 |

N/A |

0.125, 0.175 |

XYP30 |

≤30 |

≤10% |

≥75 |

N/A |

0.175 |

XYP60 |

≤60 |

≤10% |

≥75 |

N/A |

0.125, 0.175 |

XYP100 |

≤100 |

≤10% |

≥76 |

N/A |

0.125, 0.175 |

XYP120 |

≤120 |

≤10% |

≥78 |

N/A |

0.125, 0.175 |

XYP200 |

≤200 |

≤10% |

≥79 |

N/A |

0.125, 0.175 |

XYP250 |

≤250 |

≤10% |

≥80 |

N/A |

0.125, 0.175 |

XYP300CH |

≤300 |

≤10% |

≥81 |

≥0.6% |

0.188 |

XYP300AH |

≤300 |

≤10% |

≥81 |

3~5% |

0.188 |

XYP450CH |

≤450 |

≤10% |

≥82 |

≥0.6% |

0.188 |

XYP450AH |

≤450 |

≤10% |

≥82 |

3~5% |

0.188 |

|

| |

C : Cleared A : Anti-glare H : Hardcoated |

|

| |

ITO patterning customization. |

|

• Technics: screen printing / photolithography

• Pattern drawing: customer design

• Maximum patterning size: 350mm x 400mm

• Minimum feature dimension: 0.3mm |

|

| |

| |

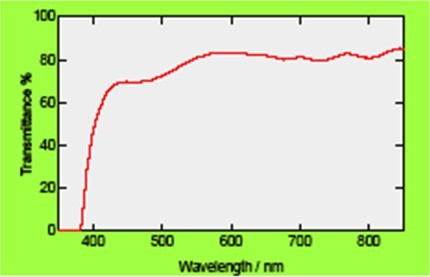

| Indium-tin-oxide (ITO) Coated PEN Flim |

| |

| Specification |

| |

| Substrate |

Polyethylene naphthalate (PEN, Teonex, Q65FA) |

| Size |

210mm x 290mm |

| Thickness of film |

0.2mm |

| Transmission @ 555nm |

>80% |

| Sheet resistance |

< 15 ohm/sq |

|

| |

|

| |

| |

| |

| |

| |

| |